Stadium Export Services Creates Custom CNC Machined Packaging Inserts for Rotary Power

Posted on March 12 2025

Stadium Export Services has delivered a bespoke packaging solution for British Engines Group Company, Rotary Power, who specialises in the design and manufacture of hydraulic motors and chemical metering pumps. This collaboration showcases Stadium’s CNC machining capabilities for pallets and cases, ensuring safe transit for Rotary Power’s components.

The Project

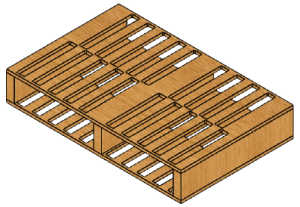

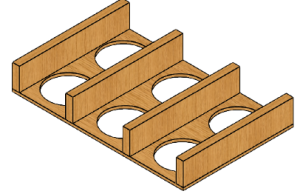

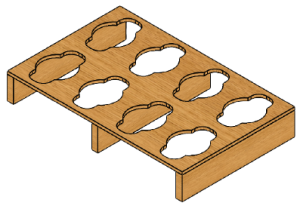

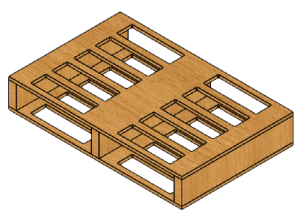

Rotary Power approached Stadium Export Services with a critical challenge; to manufacture durable custom packaging inserts, precisely tailored to fit euro pallets with pallet collars. The aim was to keep the components safely separated, avoiding any risk of damage during transit to and from heat treatment or while being moved around the facility.

Stadium Export Services provided a custom solution designed specifically to meet Rotary Power’s unique needs.

CNC Machining Capabilities

The project was completed on a Felder CNC machine, which can execute precise and complex cuts, key to producing the customised plywood inserts.

Using detailed drawings supplied by Rotary Power, the CNC machine was programmed to create a series of precise cut-outs in the plywood. These were designed in various shapes and sizes to perfectly fit and secure different components within the euro pallet. This process ensured that all parts were securely immobilised, eliminating movement and significantly reducing the risk of damage through contact with each other.

Before the CNC machine was introduced, inserts were handcrafted, which often led to inconsistencies and longer production times. The CNC machine delivers unmatched accuracy and repeatability, as well as significantly reducing production time and enhancing efficiency.

To fulfil Rotary Power’s needs, Stadium manufactured six distinct inserts in varying shapes and sizes. Once completed, the inserts were transported to Rotary Power’s facility by Stadium Export Services.

Results

Rotary Power’s Lead Manufacturing Quality Engineer, Matthew Jennings, noted with the custom packaging inserts, Rotary Power experienced a significant reduction in transit damage and a noticeable increase in packaging production efficiency.

“Stadium Export Services made a real difference for us. The custom packaging inserts they created have been a great solution for protecting our components during transit and around the facility. Their attending to detail and ability to deliver exactly what we needed has made our processes smoother and more reliable. It’s been a straightforward and positive experience working with them.” – John Smith, Production Engineer, Rotary Power

Future Investments

Beyond completing the immediate task, Stadium Export Services has also invested in enhancements to further its capabilities:

- SWOOD CAM Software Integration: This advanced software allows programming directly from customer drawings, streamlining the process and eliminating manual calculation of positioning and coordinates. This addition will also enable etching capabilities, allowing part numbers or details to be added directly onto the plywood inserts.

- Increased Capacity: To meet growing demand, Stadium has invested in a second CNC machine, ensuring faster turnaround times and greater production volumes.

By leveraging CNC technology, Stadium delivered a solution to address custom packaging needs and enhanced its long-term service capabilities. The investment in advanced machinery demonstrates Stadium’s dedication to providing precise, efficient, and reliable packaging solutions.

Find out about our bespoke case and crate manufacture services or get in touch to discuss your requirements with our team.